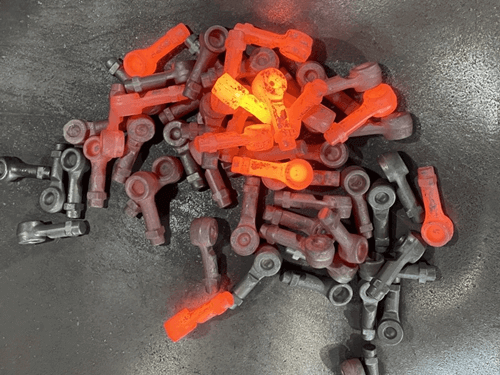

Hot die forging transforms metal billets into predetermined shapes using a series of forging dies in the manufacturing process. This technique has experienced exponential growth over the past few years due to its unique benefits. In this article, we will explore five of the hottest advantages of hot die forging that machine users should be aware of in 2023.

-

Superior Structural Integrity

Heating and deforming metal under high pressure realigns the internal grain structure, eliminating defects and voids. This enhances the microstructure, resulting in components with exceptional strength, durability, and resistance to impact and fatigue, crucial in various industrial applications.

-

Greater Design Flexibility

Hot die forging offers a high degree of design flexibility, allowing manufacturers to produce components of varying complexity and sizes. Whether it’s small intricately detailed parts or large structural components, the process can effectively shape metal billets into virtually any geometry. This flexibility empowers machine users to create custom parts tailored to specific requirements, making hot die forging an invaluable tool in today’s dynamic manufacturing landscape.

-

Economic Efficiency

The ability to produce components close to the final shape (near-net shape) reduces the need for subsequent machining operations, saving both time and money. Additionally, the high rate of production possible with automated forging presses contributes to the economic efficiency of this process, making it a preferred choice for large-volume orders.

-

Enhanced Metallurgical Properties

Apart from structural improvements, hot die forging also enhances the metallurgical properties of the forged components. The intense heat involved in the process allows for the homogenization of the alloy’s composition, leading to uniform mechanical properties throughout the part. This results in consistent performance under different operating conditions, providing machine users with the assurance of component reliability and longevity.

-

Eco-Friendly Manufacturing

In the era of increased environmental consciousness, the importance of eco-friendly manufacturing processes cannot be understated. Hot die forging stands out in this aspect. The efficient material usage in hot die forging minimizes waste production, and the reduced requirement for additional machining and finishing processes cuts down on energy consumption.

For hot die forging products, check out the link for some of the best deals.