Hot forging is one of the oldest known forms of manufacturing metallic products. The technology has been used for probably thousands of years. With technology advancements, the hot forging process has been improving and is more efficient today.

But how much do you know about hot forging? Do you know how hot forged products are made and how the process looks like? Well, for the newbies, we have put together facts about this forging that you should know. Check out the following:

The forging Use Heat

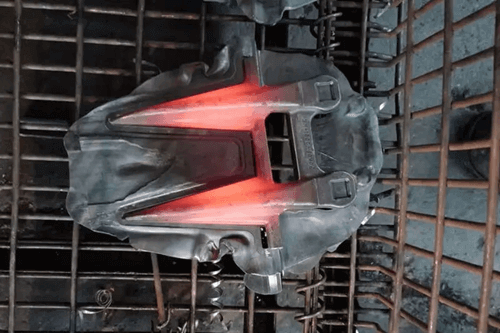

One of the biggest facts that distinguished hot forging from other forging methods is the heating of the workpiece. What is different about this forging process is the heating of the workpiece to the crystallization point. In fact, the metal piece is heated to almost a melting point where it gains plasticity. That’s why the hot forged process usually uses a lot of heat energy.

It Is The Oldest Forging Process

The hot forging process has been found to be one of the oldest metal-forming technologies in the market. For thousands of years, metal products have been found forged by heating the workpiece first. The old ways were about the use of wood as a source of heating energy. However, the modern era introduced the use of coal as a source of energy.

Use Of Electricity Energy

The hot forging process is now using electric energy for heating workpieces. This is an improvement from the use of coal, which has been said to be one of the biggest causes of global warming. The use of electricity has introduced the use of clean energy. This is from the use of green energy like solar energy.

Hot Forgings Are Super Durable

Another fact you need to know about hot forging is that it has some of the most durable forgings in the industry. Modern hot forging has some of the best quality forgings in the market. This is what has made these forgings super durable.

There are so much hot forged products consumers should know about hot forging, but these are some of the essential facts to check.